METALCOMPOSITE® | METALOOK®

Decorative metallization

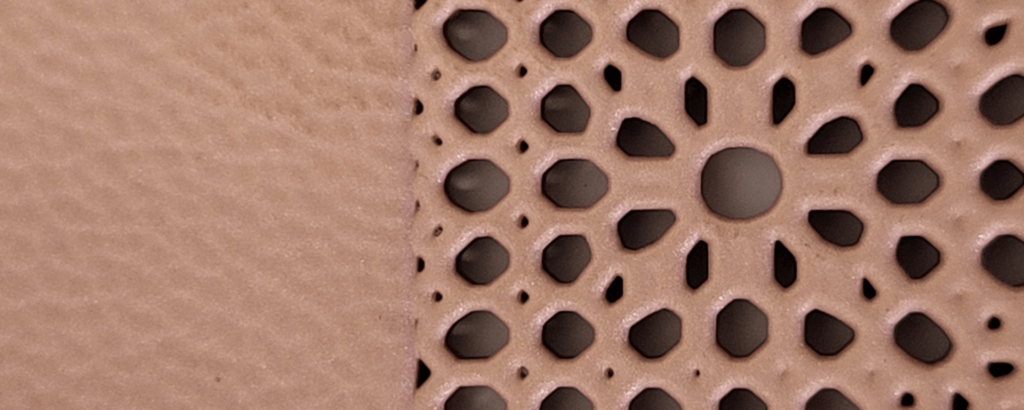

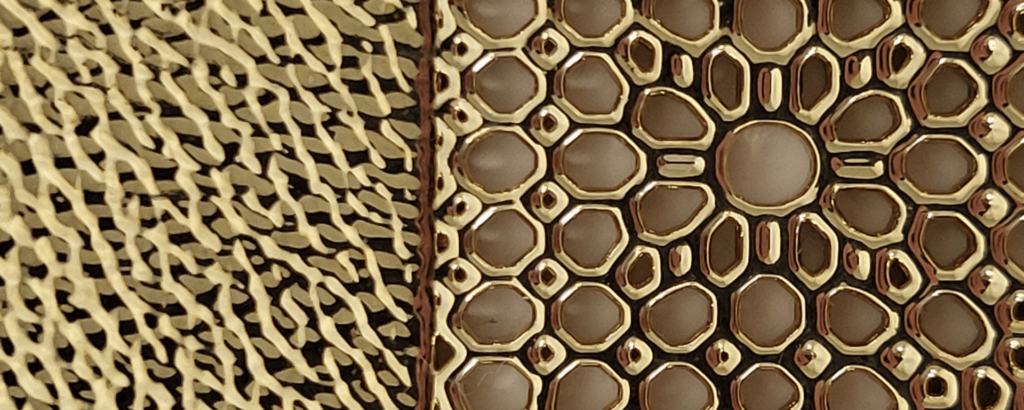

Cage Flowerbomb - VIKTOR & ROLF

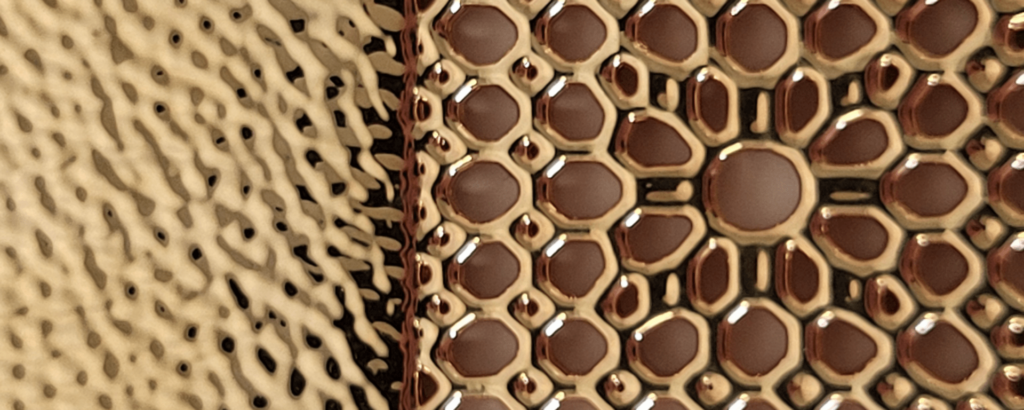

Gold, copper, silver: a variety of finishes for decorative metallization.

A variety of colors to enhance your creations

The decorative metallization offers a wide range of finishes to meet your specific project requirements.

Whether you're looking for a gold, copper or silver finish, or even bolder shades on a metal base with transparent colored varnishes, we can help you choose the colors that will enhance your creations.

Thanks to our metallization process, each piece benefits from a durable finish and a unique shine, suitable for demanding sectors such as luxury goods, art and cosmetics.

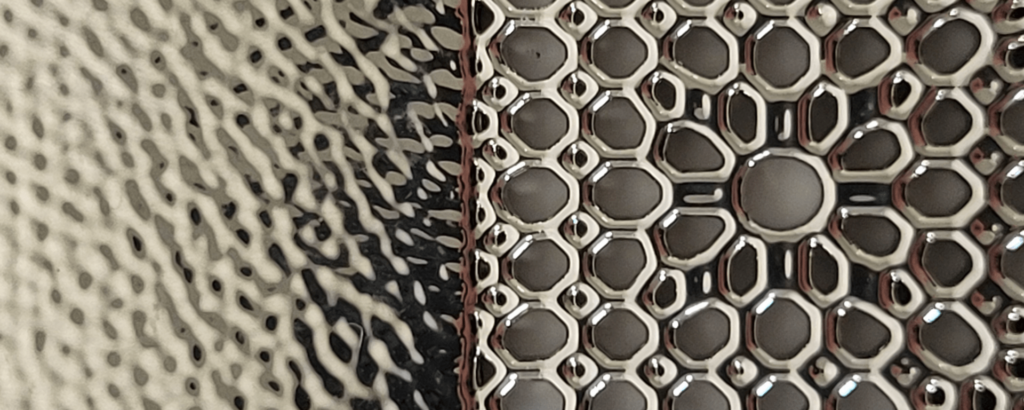

Gloss, satin or brushed finishes in decorative metallization

Top-of-the-range finishes for exceptional results

Our decorative metallization process enhances your parts with a complete range of high-end finishes. You can choose from a variety of options for a unique aesthetic finish:

- Nickel and black nickel: shiny, brushed, satin.

- Copper: shiny, brushed, satin.

- Yellow gold, pink gold, champagne: glossy, shiny, satin.

- Palladium: shiny, glossy, satin.

- Ruthenium: shiny, brilliant, satin.

- Silver: bright, shiny, satin.

- Matt black chrome

- Colored varnish: to add a touch of color while preserving the mirror-polished appearance of the metal.

Each finish is meticulously crafted to guarantee optimum quality and meet the expectations of the most demanding sectors.

Shiny copper

Satin copper

Brushed copper

Shiny nickel

Satin nickel

Brushed nickel

Shiny black nickel

Satin black nickel

Brushed black nickel

Shiny champagne gold

Satin champagne gold

Brushed champagne gold

Shiny yellow gold

Satin yellow gold

Brushed yellow gold

Shiny pink gold

Satin pink gold

Brushed pink gold

Shiny palladium

Satin palladium

Brushed palladium

Shiny ruthenium

Satin ruthenium

Brushed ruthenium

Matt black chrome

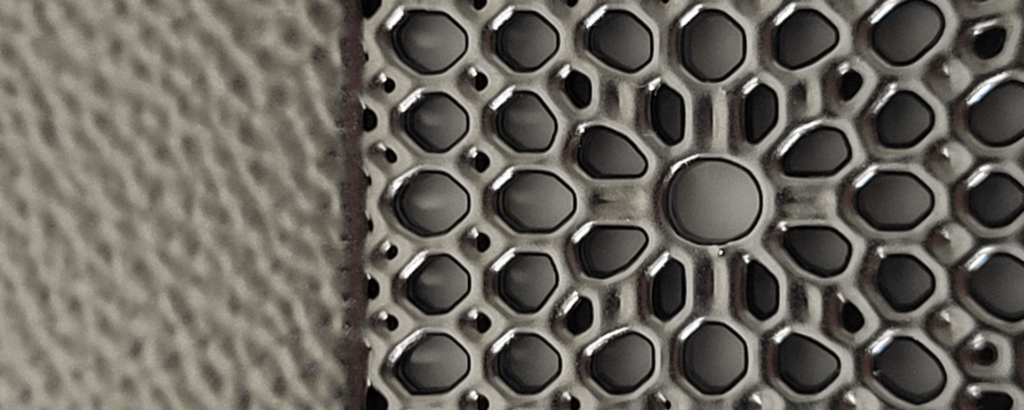

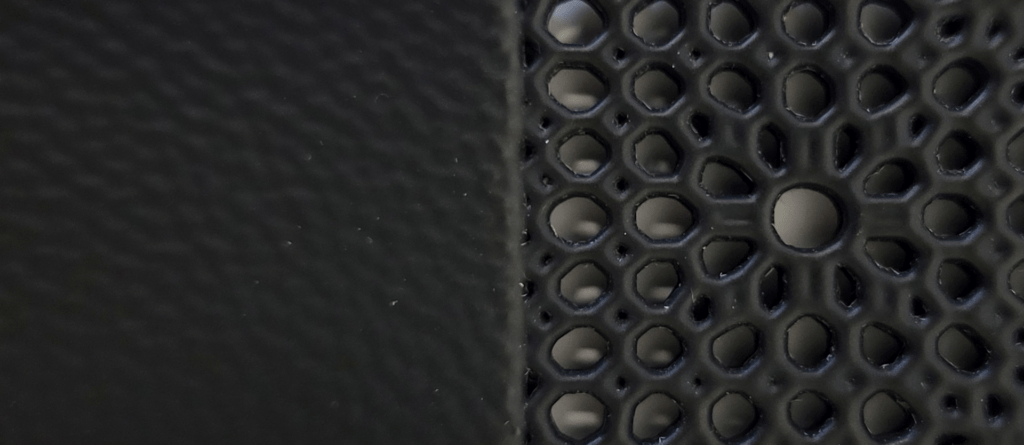

METALOOK® for aesthetic finishes in decorative metallization

METALOOK®: the elegance of aesthetic metallization

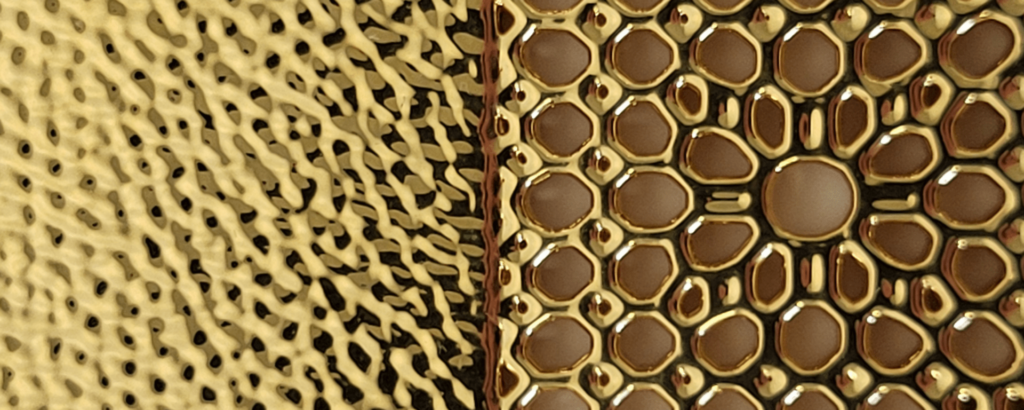

The METALOOK® process is ideal for adding an elegant metallic touch to your creations. This aesthetic deposit transforms your plastic parts into genuine metal objects, with a cold touch and a high-end finish.

METALOOK® fully satisfies the needs of the luxury goods industry. This process is perfect for cosmetic parts, decorative elements, haute-couture pieces, works of art, trophies... Thanks to METALOOK®, your projects gain in visual and sensory appeal.

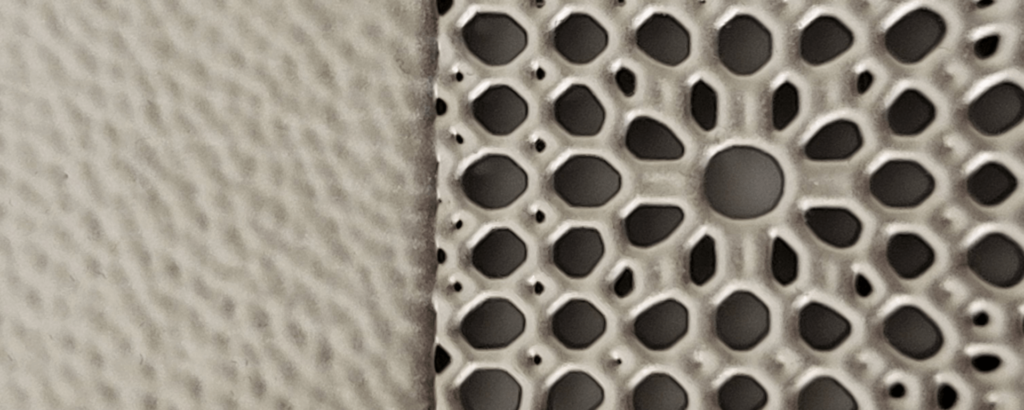

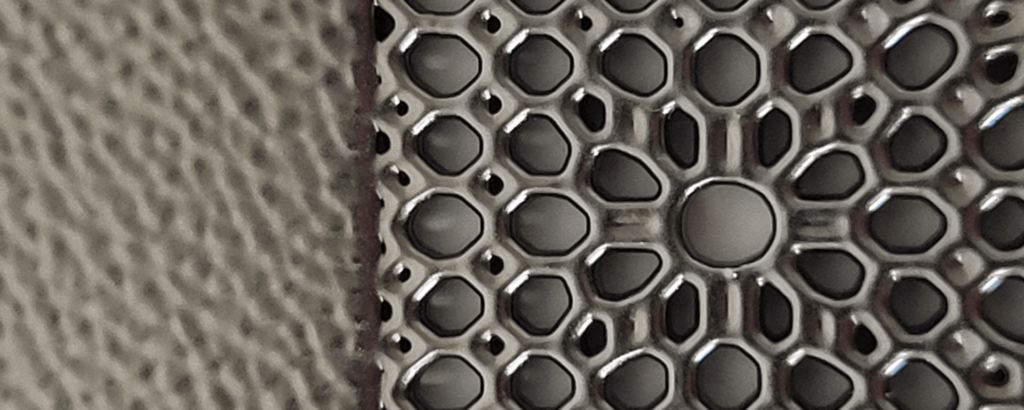

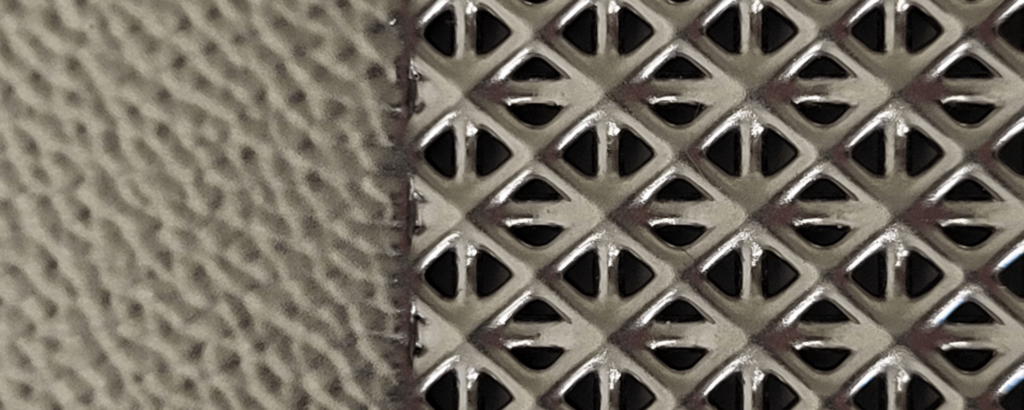

METALCOMPOSITE® for tough, high-performance parts

METALCOMPOSITE®: resistance

in addition to elegance

The METALCOMPOSITE® solution makes it possible to achieve an aesthetic finish while improving the mechanical properties of your parts, thanks to thick metal deposits. This unique process increases the mechanical strength of aesthetic parts, while also providing impact resistance, optimized temperature resistance, effective protection against abrasion...

This technology is particularly well-suited to demanding projects: functional parts, parts exposed outdoors or subject to stress, fragile manufacturing parts.

With METALCOMPOSITE®, every part benefits from unrivalled strength and durability, while meeting the aesthetic criteria of every project.

Aesthetic metal deposition solutions for all substrates

Metallization for a wide variety of materials

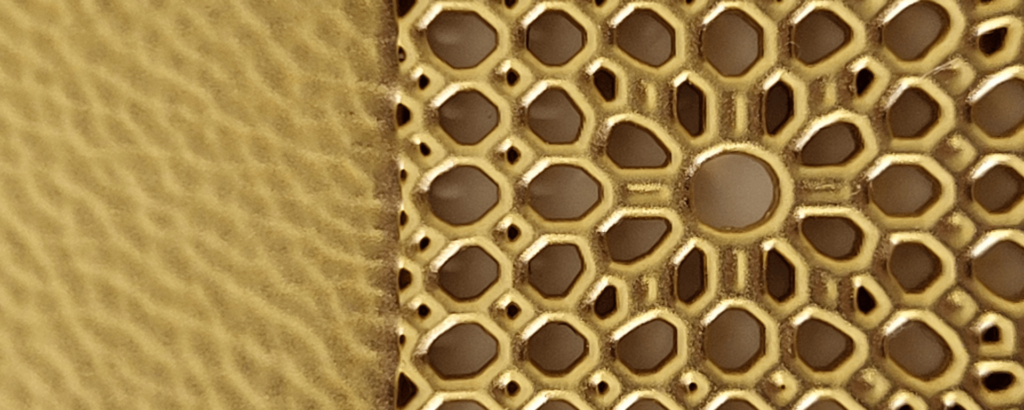

Electroforming metallization can be applied to a wide range of substrates, both conductive and non-conductive. Thanks to our advanced processes, we can metalize plastic, composite, glass, metal or 3D-printed parts, while guaranteeing perfect adhesion and a high-end finish.

Compatible materials :

- 3D printing: SLA, SLS, FDM, MJF, DLP...

- Plastics and composites: PA, ABS, PC, PEEK, PEKK, PVC, PEI, carbon, fiberglass...

- Metals: steel, aluminium, bronze, brass, stainless steel,

- Glass

- Resin

Depending on the type of material and the desired application, we select the most suitable metallization process, whether METALOOK® for an aesthetic finish or METALCOMPOSITE® for improved mechanical performance in addition to aesthetics.

Metallization of large parts

Processing large parts

Thanks to our state-of-the-art equipment, we can handle large parts.

Our big electroforming baths enable us to metallize large-size and heavy parts:

- Nickel matt: 6800 x 3800 x 2400 mm

- Shiny nickel: 2700 x 1400 x 1000 mm

- Shiny copper: 2700 x 2400 x 1400 mm

- Precious metals: 500 x 500 x 500 mm

With a lifting capacity of up to 6.4 tonnes, we meet the requirements of the artistic and architectural sectors, offering tailor-made solutions for the most ambitious projects.

Art, design, luxury: a wide range of applications for decorative metallization

Multiple applications for your projects

Decorative metallization can be used in a wide range of fields, thanks to its ability to combine aesthetics and technology.

Our solutions are ideally suited to the following sectors:

Art: sculptures, works of art, reproduction

Design: furniture, decor, trophies

Luxury: haute couture pieces, cases for spirits

Architecture: decorative elements, ornaments

Jewelry: bracelets, accessories, fashion pieces

Leather goods: handbag handles and accessories

Cosmetics: perfume bottles, accessories

Automotive: aesthetic parts for concept cars or luxury limited series.

Watchmaking: watch cases, decorative parts

Aeronautics: VIP cabin decor parts

All about

Smart Metal Design

Do you have any questions about our electroforming metallization processes, finishes or applications? Find all the answers in our FAQ, designed to guide you and help you better understand our expertise.

What is the minimum quantity?

There's no minimum, we process single parts, prototype parts.

What level of finish should be applied to parts to be metallized?

Metallization reproduces the surface finish. So if you want a smooth finish, you'll need to

sandpaper the part with 600 grit, taking care to ensure that the grit falls evenly. If necessary, it can be best to apply a coat of primer before sanding to fill in any

defects.

Can all substrates be metallized?

Parts are immersed in acid baths during the plating process, so it is essential that

parts are watertight and acid-resistant. Plaster-type materials are to be avoided.

Materials such as sponge, fabric and plants can be metallized, but they must be saturated with resin beforehand.

résine au-préalable.

For parts manufactured using FDM, it is important to provide a dedicated surface prepapartion ensuring the parts are perfectly sealed, otherwise bleeding will occur

(the acid will come out of the part). resulting in metallization degradation and

blistering).

For parts manufactured in SLS or MJF, it is necessary to do a chemical etching or

apply a varnish to fill in surface porosities.

Do flexible parts stay flexible after metallization?

Even thin metallization will stiffen the part, depending on the geometry it is possible to

keep a little bit of flexibility

What precautions should be taken when assembling?

It is necessary to anticipate an offset taking into account the thickness of the metal to be deposited. It is better to ask us what gap you should consider before starting

manufacturing the parts. The gap won't be the same from an area to another on the same part.

pièce le jeu à prévoir ne sera pas le même.

Does the metal coating resist to outdoors exposure?

Yes, but it is important to let us know that it's for outdoor use, as the thickness deposited

will not be the same, and depending on the finish, we recommend that you apply a varnish.

Metal can become tarnished over time, but can be revived with polishing paste

to regain its original brilliance.